Adhesion Testing

Since 1998, DFT Instruments has been the UK’s exclusive distributor of DeFelsko adhesion testing instruments, helping inspectors and contractors verify that coatings are securely bonded to their substrates. Adhesion testing is critical in industries ranging from marine and aerospace to automotive, manufacturing, and construction, where coating failure can lead to costly rework, downtime, or structural damage.

Adhesion is more than just a number—it’s the assurance that protective and decorative coatings will perform as intended under real-world conditions. With both manual and automatic pull-off adhesion testers and cross-hatch testers, DFT Instruments offers reliable solutions for different substrates, coating types, and industry requirements.

As a DeFelsko Authorised Service Centre (DASC), we don’t just supply instruments—we also calibrate, service, and support them locally here in the UK. That means fast turnaround, certified calibration, and expert guidance, every time you test.

Why Testing Matters

-

Prevent Costly Failures – Poor adhesion leads to peeling, blistering, and delamination—risks that can halt projects or damage reputation.

-

Meet Standards & Specifications – Many industries require adhesion testing to ISO, ASTM, and BS EN standards for compliance and quality assurance.

-

Support Warranty & Contracts – Documented adhesion results provide traceable proof for customers, auditors, and regulators.

-

Optimise Application Process – Testing highlights where surface prep, primers, or application methods need improvement.

-

Confidence in Coating Longevity – Adhesion strength directly impacts how coatings perform against wear, corrosion, and environmental stress.

Why Choose DFT?

-

Exclusive UK Distributor of DeFelsko – Genuine instruments with full local support since 1998.

-

DeFelsko Authorised Service Centre (DASC) – Factory-approved calibration and repair carried out here in the UK.

-

Wide Range of Solutions – From portable pull-off testers to simple cross-hatch cutters, we offer the right tool for every job.

-

Fast UK Turnaround – Most services and calibrations completed within one working day.

-

Traceable Certificates Included – Every tester supplied or serviced comes with a calibration certificate traceable to UKAS/NIST/PTB.

-

Local Expertise – Speak directly to our UK technicians for advice on selecting and using adhesion testers.

Our Services

-

Calibration & Recalibration – Ensure results remain precise and compliant with international standards.

-

Repair & Maintenance – Genuine parts and factory-approved service keep your instruments performing like new.

-

Training & Guidance – From proper pull-off technique to interpreting cross-hatch results, we support your team on site and in the lab.

-

Preventative Care – Extend instrument life with regular servicing and handling advice.

-

Firmware & Software Updates – Keep PosiTest AT models current with the latest features and compatibility.

Helpful Adhesion Testing Videos

PosiTest AT Series 10:02

This overview of the PosiTest® AT Pull-Off Adhesion Tester explains the general operation and procedure of performing an adhesion test.

Manual Adhesion Tester 9:29

Instructional video for the PosiTest AT-M Manual Adhesion Tester

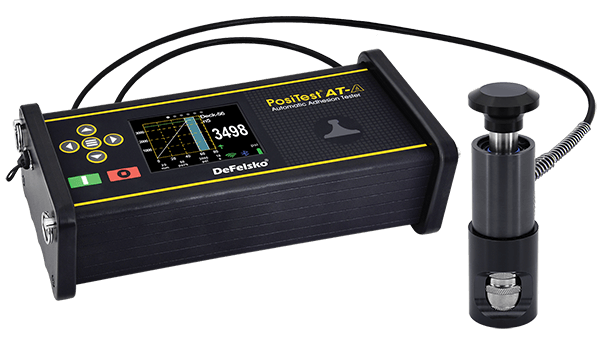

Auto Adhesion Tester 0:24

A short video clip of the PosiTest AT Automatic Adhesion Tester

Adhesion Test Method Comparison

Which Adhesion Test Method is Right for You?

Choosing between cross-hatch and pull-off testing depends on your project, substrate, and reporting needs. Use the guide below to compare the three main options we supply — from quick visual checks with the PosiTest CH, to full quantitative pull-off testing with the PosiTest AT-M or AT-A. This table will help you decide which instrument best fits your application.

| Feature | Cross-Hatch (PosiTest CH) | Manual Pull-Off (PosiTest AT-M) | Automatic Pull-Off (PosiTest AT-A) |

|---|---|---|---|

| Test Method | Lattice cut + tape removal | Hydraulic pull using manual pump | Hydraulic pull with electronic pump |

| Result Type | Qualitative (visual grade) | Quantitative (MPa / psi value) | Quantitative (MPa / psi value) |

| Best For | Paints, lacquers, and powder coatings on rigid substrates | Protective coatings on metals, wood, and concrete | High-precision inspections on structural coatings |

| Standards | ISO 2409, ASTM D3359 | ISO 4624, ASTM D4541, EN, BS | ISO 4624, ASTM D4541, EN, BS |

| Advantages | – Fast and inexpensive – Simple to use – Ideal for routine checks |

– Portable and rugged – Cost-effective – Reliable in field conditions |

– Highest consistency – Eliminates operator influence – Advanced data storage & reporting |

| Limitations | – Visual only, no numeric value – Not for thick/flexible/brittle coatings |

– Requires manual pumping – Slightly more operator-dependent |

– Higher cost – Requires battery charging |

| Data Handling | None (visual classification) | Stores up to 200 readings USB export via PosiSoft |

Stores up to 100,000 readings USB, WiFi & Bluetooth connectivity |

| Typical Applications | Production lines, quality control checks, automotive, appliances | Routine field inspections, concrete overlays, protective steel coatings | Critical inspections, aerospace, marine, oil & gas, compliance audits |

Our Adhesion Testers

Adhesion Testing Instruments We Offer

| Model / Method | Description | Best For |

|---|---|---|

| PosiTest AT-A Automatic | Fully automated hydraulic adhesion tester with controlled pull rate & on-screen results. | High-precision, repeatable testing where accuracy and compliance are critical. |

| PosiTest AT-M Manual | Portable, mechanical pull-off tester with simple, rugged design. | Field use, quick checks, or budget-sensitive projects. |

| PosiTest CH Cross-Hatch | Simple cutting tool for lattice pattern adhesion checks. | Paints and coatings on thin, rigid substrates (ISO 2409 / ASTM D3359). |

Whether you need a portable pull-off tester for structural steel or a simple cross-hatch tool for paint inspection, DFT provides UK-supplied instruments, local calibration, and expert advice.

📞 Reach out to our UK team. 01442 879494 or Complete the form.