| Specification | Detail |

|---|---|

| Microscope Magnification | 50× with precision optics & rotating scale in both Metric & Imperial units |

| Maximum Coating Range | Up to ~1,250 µm (50 mils) with 1X tip; less with higher magnification tips |

| Power Source | 1 × AAA battery (for built-in light) |

| Housing / Build Material | Anodised aluminium with rotating cutting tip holder |

| Standards Compliance | ISO 2808 / 19399, ASTM D4138, JIS K 5600-1-7, NF T30-123 |

| Warranty | 2 years (body & parts) |

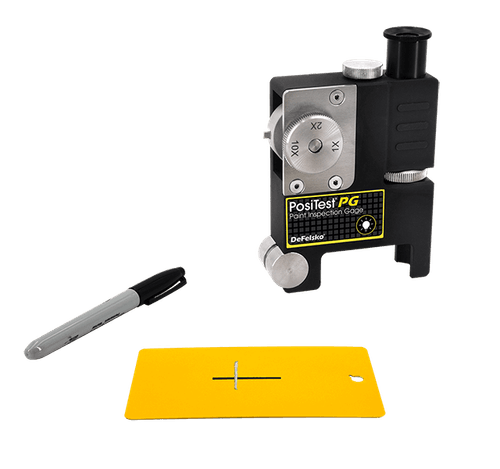

| Kit Includes | PosiTest PG, cutting tips (1X, 2X, 10X), hex key, AAA battery, black marker, calibration certificate, instructions, custom case. |

PosiTest PG

Precise, Destructive Coating Thickness Measurement

The PosiTest PG is a rugged inspection tool that cuts a small groove through paint or coating to measure its total or individual layer thickness. By observing that groove under a built-in microscope, you get reliable destructive measurement—ideal for spot checks, quality control, or situations where non-destructive methods aren’t sufficient.

Supplied in the UK by DFT Instruments, every PosiTest PG comes ready to use with a long-form certificate, all necessary accessories, and full local support so your inspections are accurate, traceable, and inspection-ready.

Features

-

Built to Last – Strong, anodised-aluminium housing provides excellent durability for demanding inspection environments.

-

Multi-Tip Cutting Head – A rotating holder accepts up to four cutting tips, allowing quick changes and versatile measurement without downtime.

-

Precision Optics – Integrated 50× microscope delivers sharp, detailed views, with a rotating measurement scale marked in both metric and imperial units for easy reading.

-

Certified Accuracy – Delivered with a long-form Calibration Certificate fully traceable to NIST standards for audit-ready documentation.

-

International Standards Compliance – Meets or exceeds key specifications including ISO 2808, ISO 19399, ASTM D4138, JIS K 5600-1-7, and NF T30-123 for trusted, globally recognised performance.

Why Measuring Matters

-

Confirm Actual Film Deposition – When coatings are layered or when paint is over galvanizing or enamels, it’s often hard to be sure of the exact film thickness. The groove cut by the PG reveals exactly what’s there.

-

Layer-by-Layer Analysis – For multi-coat systems (especially those with different colours), the PG allows you to distinguish between layers—helpful to verify primers, topcoats or finishes as per specification.

-

Suitability for Rigid Substrates – Works best on metal, plastic, wood, or rigid surfaces where you can make a mark and cut a groove. Useful for panels, switch-plates, machinery, automotive parts etc.

-

Compliance & Auditable Results – Meets standards like ISO 2808 / 19399, ASTM D4138, JIS K 5600-1-7, NF T30-123, giving confidence in results for audits, QC reports, or contract verification.

Why Choose DFT?

-

Long UK-based Experience – Since 1998, DFT Instruments has been supplying and supporting coating inspection and QA tools in the UK. We know what users really need and the pitfalls in the field.

-

Full UK Support & Calibration – Your PosiTest PG arrives with a long-form calibration certificate traceable to NIST/PTB, and our UK service centre handles any recalibrations or parts quickly.

-

Complete Accessory Pack – Supplied with multiple cutting tips, microscope optics, a case, marker, battery etc.—you’re ready to measure immediately.

-

Field Proven Durability – Rugged anodised aluminium housing, rotating tip carriage, and built-in light mean it’s built for real-world use.

-

Expert Advice & Tips – We’ll help with selecting cutting tips, interpreting cuts, ensuring surfaces are properly prepared, and training staff—so that earlier mistakes are avoided and results are consistent.

Features & Benefits

-

Microscopic precision with 50× magnification, letting you see very fine detail in the groove for better layer discrimination.

-

Multiple cutting tip options (1X, 2X, optional 5X, 10X) so you can adjust for thicker or thinner coatings.

-

Built-in bright white light with timer and eye-friendly optics, so you can see clearly with or without glasses.

-

Durable construction: anodised aluminium body, rotating cutting tip holder, strong carriage, and long-lasting materials.

-

Uses a single AAA battery for light; simple to maintain.

-

Kit includes essentials: cutting tips, marker, hex key, case, calibration certificate etc., so no extra purchases are needed for basic operation.

Technical Specifications

Comparison Table: Model / Cutting Tip Performance Comparison

| Cutting Tip | Conversion Factor | Coating Range | Accuracy* |

|---|---|---|---|

| 1X | 1 × | 0-1,250 µm / 0-50 mils | ±25.4 µm / ±1 mil |

| 2X | 0.5 × | 0-625 µm / 0-25 mils | ±12.7 µm / ±0.5 mil |

| 5X (opt) | 0.2 × | 0-250 µm / 0-10 mils | approx. ±0.1 mil / ±2.5 µm (depending on tip) |

| 10X | 0.1 × | 0-125 µm / 0-5 mils | ±2.5 µm / ±0.1 mil |

*Accuracy depends on cutting tip chosen and condition of the tip. Precision cuts require a sharp tip.

FAQ’s

What substrates can I use the PG on?

Any rigid substrate—metal, plastic, wood—so long as you can mark the surface and make a clean cut.

How do I choose the correct cutting tip?

Use the conversion chart. If you don’t know the thickness, start with the 2X tip and adjust up or down depending on how thick or thin your coating turns out.

Can I measure multiple layers?

Yes, if the layers are contrasting in colour. The PG allows you to distinguish individual layers in a multilayer paint/coating system.

Does it work on curved or small parts?

It’s best used on flat or moderately curved surfaces. The guide wheel helps keep the cut straight; very small diameters may challenge alignment. Pipes of around 25 mm diameter can be managed when measuring axially.

When should I replace a cutting tip?

If it becomes dull or damaged, which affects the sharpness of the cut. Replacing the tip restores accuracy.

How do I read the measurement?

After marking and cutting, view the groove with the microscope, align the reticle, count the graduation marks, then multiply by the conversion factor for the tip you used.

Is calibration included?

Yes. Each PosiTest PG comes with a traceable long-form certificate (NIST) so your measurements are auditable.

What happens when the built-in light is off or battery dies?

The measurement function still works (cutting and microscope view), but lighting may be poor. Replace the AAA battery to restore the light. The light also features an auto-off timer to conserve power.

Still need help?

If you experience an issue, check our troubleshooting guide or contact our support team directly. As a DeFelsko Authorised Service Centre (DASC), DFT Instruments provides calibration, repair, and technical assistance locally in the UK.

Find out more about the PosiTest and all the features that come with it

What’s Included:

-

PosiTest PG gauge body

-

Cutting tips: 1X, 2X, 10X

-

Optional storage of 5X tip available separately

-

1/8-inch hex key for changing tips

-

AAA battery (for built-in light)

-

Permanent black marker for user marking

-

Long-form calibration certificate traceable to NIST/PTB

-

Instruction manual & quick reference guide

-

Custom carrying case

-

2 year warranty

Need precise, layer-by-layer coating measurements for quality assurance or contract compliance? The PosiTest PG Paint Inspection Gauge gives you destructive accuracy where non-destructive just won’t do. Supplied by DFT Instruments with full calibration, accessories, and UK-based service.

📞 To enquire about this product, contact our team today on: 01442 879494 or Complete the form.